- Dealer Enquiry Form

- mailto: info@scoto.in

- Mon - Sat: 9:30AM - 6:45PM

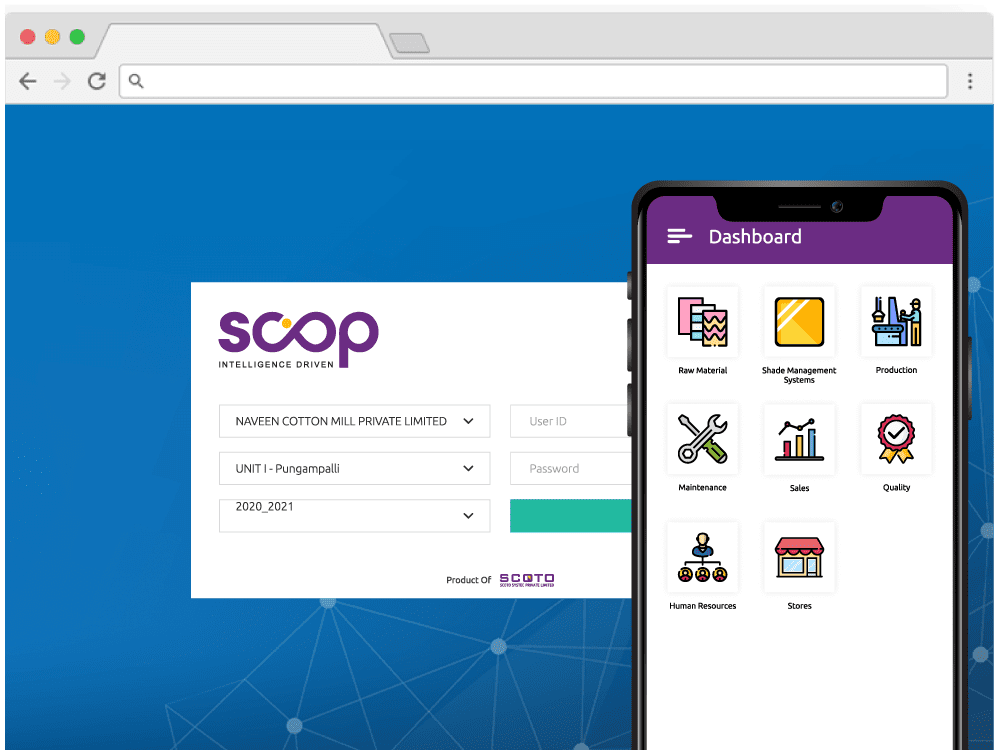

ERP for Spinning and Textile Industry

The textile business is influenced via irregularity, fluctuating interest, handling limit requirements, and high working expenses. Regardless of whether you are into the cotton-to-yarn, yarn-to-texture, or texture to-passing on preparing section or every last bit of it, Scop ERP can help in running tasks easily.

The spinning business gets intensely influenced because of occasional rage. The costs of cotton and other crude materials prod high as can be. Because of this, the business can confront a tremendous decrease underway. For such occasions, the spinning and textile industry ought to be set up with additional stock to adapt up to occasional obstacles. ERP software for the spinning and textile industry appropriately deals with the whole stock effectively. ERP software for spinning assumes a significant part in keeping the business unblemished.

- Execution of ERP for turning industry lessens the operational expense of business and industry, as postponements are totally dispensed with.

- All the information and data is put away midway, so at whatever point required the data can be brought at any occasion.

- Money and records module helps in keeping up appropriate record records of exchanges and keeps report.

- Monetary record can be set up in a single tick.

- ERP for material industry incorporates the whole framework, making a between associated organization of offices and divisions for consistent correspondence.

- Stock administration module in ERP for material and turning industry monitors secured crude material, and items by dispensing them with parcel/chronic number.

- Cotton bundles buy Storing the bunch number-wise subtleties: weight, quality, and so forth

- Giving Cotton on bundles no., in this manner keeping Inventory bunch no. insightful

- Catch Production with Carton no. in this way keeping completed Inventory container no. savvy

- All internal and outward development is followed at Security Gate, Weighbridge, Quality lab, and store/yard areas

- Plant development: different situations including Inward, Outward, Stores Related, Purchase or Sales Return, Rake Inward, Inter-Yard Transfers, Waste or Scrap development, and so on

- Recognizability all through the assembling interaction: Track parcels by style, shading, size, reach and quality

- Oversee Division savvy and united money books Costing/effectiveness , Ledgers and Profitability. Entomb division Sales and Purchase consistently

- Consumption examination for subcontracting, creation and so on

- Records endorsement and bill passing for Purchase, Services (jobwork/workers for hire) or Freight situations

- Material expenses, Overhead expenses and Process savvy costs; nitty gritty item costing and difference investigation to control item costs

- Different Stock MIS with 10 level drill down: Group->Entity->Division->Plant->Dept->Cost Center->Equipment->Item Group->Item->Issue Slip

- Transfer Sale exchanges: Stock exchange receipt for transfer specialist and hence solicitations according to real deals.

- Shift insightful Production with Batch, Lot and Godown Control

- Standard to genuine yield computations to oversee change investigation

- Quality Control: connecting of value boundaries at internal, creation and outward stage

- Refined and Accurate MIS on Production Costing/Plant Performance

- Plant support to run activities easily and lessen closures.

- Transfer Sale exchanges: Stock exchange receipt for transfer specialist and hence solicitations according to real deals.

- Enquiry and Quotation followed by three level request cycle: Sales Contract, Sales Order and Delivery Orders.

- Deals e-invoicing created quickly, by connecting to Weighslips and Delivery Orders.

- Adaptable valuing strategies cash limits, amount limits, fixed period deals, credit control and so forth

Registration Module

Sales Registration Module

Raw Material Inventory Module

Raw Material Stores Module

Spinning Stores Inventory Module

Spinning Stores Module

Spinning Direct Stock Entry Module

Spinning Production Module

Spinning Machine Maintenance Module

Sales Module

HR Payroll Module

Payment Module

Receipts Module

Banking Module

Financial Accounting Module

User Admin Module

Register/Report Module

MIS Module

SMS/Alert Module

Year Transfer Module